KSW PROCESS®

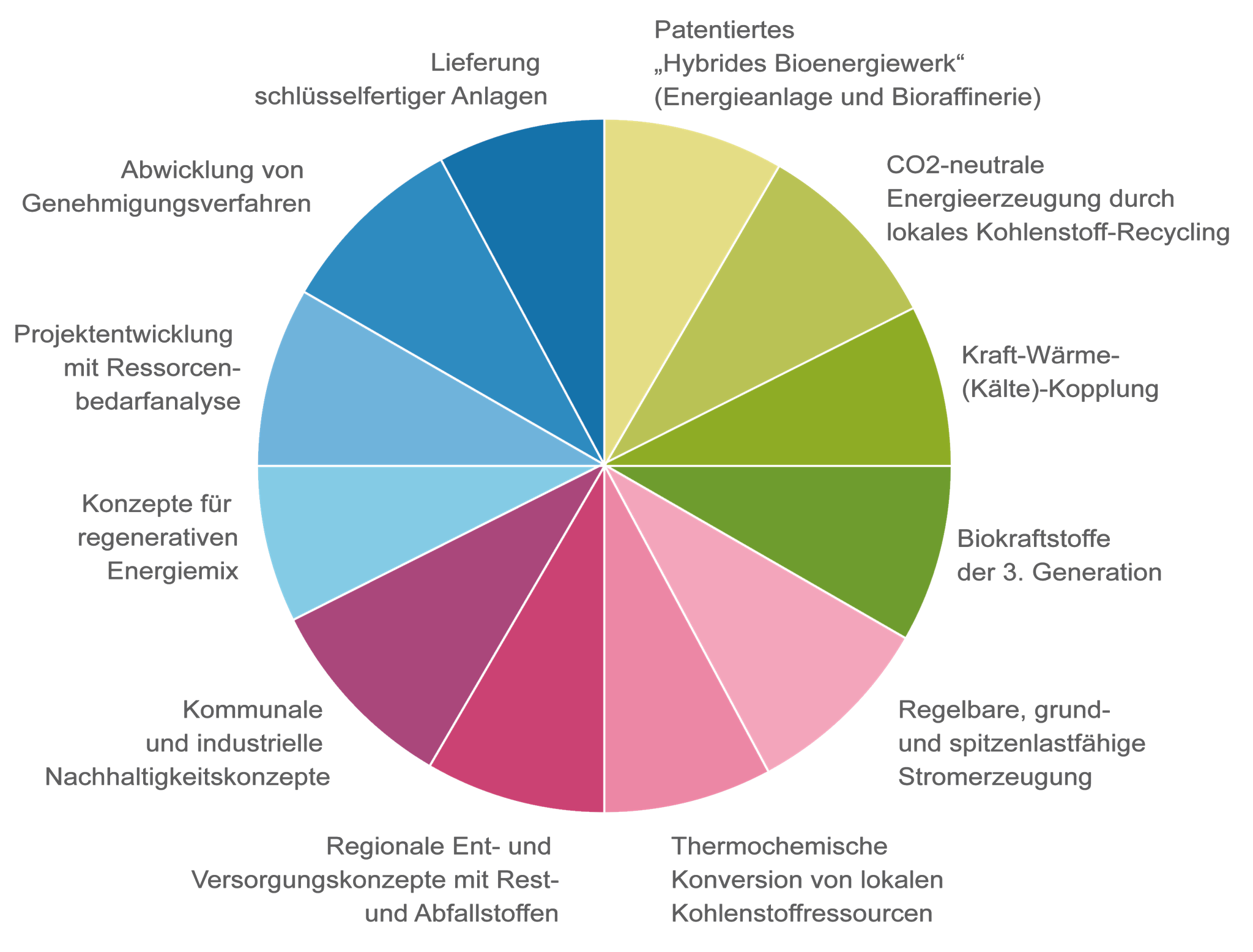

KSW Bioenergie GmbH was founded in 2004 and, as a technology and project developer, has developed and patented a decentralized "hybrid energy plant" (combined heat and power plant and biofuel production) in the form of a two-stage process (KSW-Process®). It covers the entire process sequence from the receipt and preparation of the raw material to the production and delivery of the generated energy products .

The objective of the KSW-Process® is the carbon recycling of regionally accruing biogenic and organic residual and waste materials (exclusively NONFOOD material) and their conversion into useful energy and storable bio-fuels. As a highly efficient climate protection measure, electricity, heat and cold, methanol and OME are produced as 2nd generation bio-fuel using the KSW-Process®.

The climate-friendly electricity is CO2-neutral, base-load capable with over 8,000 annual hours and at the same time controllable. This makes it an ideal complement to volatile power generation from wind and solar. Along with the continuous power generation secured in this way, an economical and climate-friendly production of "green" hydrogen can be ensured and expanded even more in the future.

The climate-neutral heat is used as process heat in nearby companies or, via local or district heating networks, for heating and/or cooling buildings.

With the completely CO2-neutral biofuel OME, existing vehicles with modern engines can be operated in a climate-friendly manner without costly conversion. The use of OME can already be an immediate and efficient measure against climate change in the transition period to fully electric and hydrogen-powered vehicles. KSW is a member of the DIN technical committee for standardizing OME as a standard fuel (DIN 51699).

KSW climate protection plants relieve the burden on the power grid as decentralized CHP plants with an electrical efficiency of approx. 40 % and an overall efficiency of approx. 80 %. They are built with demand-oriented electrical outputs between 5.0 MWel and 50.0 MWel per module. Design and operation will be carried out within the framework of regionally adapted supply and demand concepts. All types of carbon-containing, organic materials from a region, such as biogenic residual and waste materials from agriculture and forestry, contents of the organic waste garbage can, residues from composting plants or sewage sludge can be used as fuel ("carbon-recycling").

KSW Bioenergie GmbH cooperates with the following partner companies in the development of the KSW Process®, among others:

- MAN Diesel & Turbo, development of dual-fuel two-stroke marine diesel engines as the core unit of the KSW Process® for stationary operation with special fuels.

- Fraunhofer Institute Magdeburg

- CUTEC Institute of the TU Clausthal-Zellerfeld

Due to the decentralized plant concept and the high flexibility, KSW climate protection plants can completely replace natural gas and coal-fired power plants. Thus, as a "lighthouse technology", the KSW Process® has the potential to become one of the essential basic building blocks of the national but also of the global energy transition.

KSW Bioenergie GmbH was founded in 2004 and, as a technology and project developer, has developed and patented a decentralized "hybrid energy plant" (combined heat and power plant and biofuel production) in the form of a two-stage process (KSW-Process®). It covers the entire process sequence from the receipt and preparation of the raw material to the production and delivery of the generated energy products .

The objective of the KSW-Process® is the carbon recycling of regionally accruing biogenic and organic residual and waste materials (exclusively NONFOOD material) and their conversion into useful energy and storable bio-fuels. As a highly efficient climate protection measure, electricity, heat and cold, methanol and OME are produced as 2nd generation bio-fuel using the KSW-Process®.

The climate-friendly electricity is CO2-neutral, base-load capable with over 8,000 annual hours and at the same time controllable. This makes it an ideal complement to volatile power generation from wind and solar. Along with the continuous power generation secured in this way, an economical and climate-friendly production of "green" hydrogen can be ensured and expanded even more in the future.

The climate-neutral heat is used as process heat in nearby companies or, via local or district heating networks, for heating and/or cooling buildings.

With the completely CO2-neutral biofuel OME, existing vehicles with modern engines can be operated in a climate-friendly manner without costly conversion. The use of OME can already be an immediate and efficient measure against climate change in the transition period to fully electric and hydrogen-powered vehicles. KSW is a member of the DIN technical committee for standardizing OME as a standard fuel (DIN 51699).

KSW climate protection plants relieve the burden on the power grid as decentralized CHP plants with an electrical efficiency of approx. 40 % and an overall efficiency of approx. 80 %. They are built with demand-oriented electrical outputs between 5.0 MWel and 50.0 MWel per module. Design and operation will be carried out within the framework of regionally adapted supply and demand concepts. All types of carbon-containing, organic materials from a region, such as biogenic residual and waste materials from agriculture and forestry, contents of the organic waste garbage can, residues from composting plants or sewage sludge can be used as fuel ("carbon-recycling").

KSW Bioenergie GmbH cooperates with the following partner companies in the development of the KSW Process®, among others:

- MAN Diesel & Turbo, development of dual-fuel two-stroke marine diesel engines as the core unit of the KSW Process® for stationary operation with special fuels.

- Fraunhofer Institute Magdeburg

- CUTEC Institute of the TU Clausthal-Zellerfeld

Due to the decentralized plant concept and the high flexibility, KSW climate protection plants can completely replace natural gas and coal-fired power plants. Thus, as a "lighthouse technology", the KSW Process® has the potential to become one of the essential basic building blocks of the national but also of the global energy transition.

Highest environmental requirements- Economic solutions Energy and environmental technology from a single source

KSW Bioenergie GmbH

Mainzer Str. 143

D-53179 Bonn

Fon: +49 (0) 228 98 77 00

Fax: +49 (0) 228 98 77 020